Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Apr 27, 2020 18:27:01 GMT

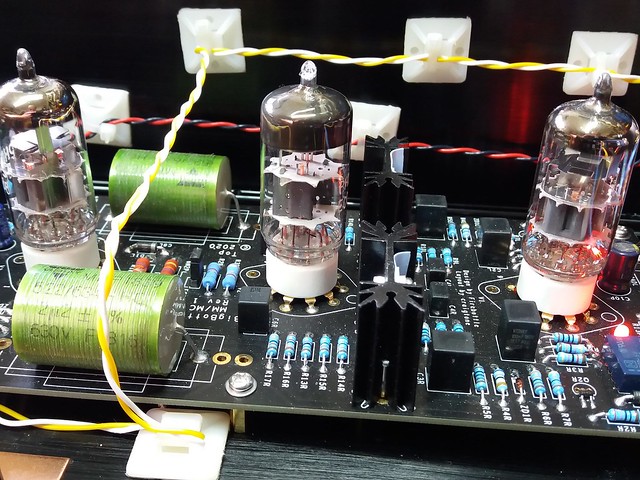

Almost all parts arrived now with transformer expected this week (you'll be pleased to hear yours is included Oli!). Work to start now on chassis which is surprisingly heavy and quite well made....dry-assembled with BBS pcb for scale in 2nd picture:    Lots of work to do.... |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Apr 27, 2020 18:45:04 GMT

Nice, what case is that?

oh and where are the transformers coming from, that place in Norfolk is it?

|

|

|

|

Post by electronumpty on Apr 27, 2020 18:47:05 GMT

Cool, I think you're gonna like it, sounds great.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Apr 27, 2020 18:55:25 GMT

Nice, what case is that? oh and where are the transformers coming from, that place in Norfolk is it? I don't have the case details to hand but will dig them up as it might be useful for others. I think it was about £80 delivered which wasn't too bad. Usual Chinese fare but nicely made and very robust. Needs a fair few holes forming in the panels though! Transformers are not coming from Sowters, no. I have all that sort of thing done by the same specialist outfit that I use for my inductor designs. They're not that well known in audio circles and do a lot for operations like the aerospace industry. I won't be sharing their details if it's all the same as they do this work as a favour to me and don't wish to deal direct or in one off's for anyone but their commercial clients. I'm lucky enough to be included on their list in an arrangement with another company. Post edit: Case details below. It was from Douk Audio: www.ebay.co.uk/itm/Douk-Audio-Aluminum-Chassis-Case-for-Amplifier-DIY-Preamp-Enclosure-Cabinet-Box/261686263109?ssPageName=STRK%3AMEBIDX%3AIT&_trksid=p2057872.m2749.l2649 |

|

Bigman80

Grandmaster

The HiFi Bear/Audioaddicts/Bigbottle Owner

The HiFi Bear/Audioaddicts/Bigbottle Owner

Posts: 16,399

Member is Online

|

Post by Bigman80 on Apr 27, 2020 19:22:05 GMT

Nice, what case is that? oh and where are the transformers coming from, that place in Norfolk is it? I don't have the case details to hand but will dig them up as it might be useful for others. I think it was about £80 delivered which wasn't too bad. Usual Chinese fare but nicely made and very robust. Needs a fair few holes forming in the panels though! Transformers are not coming from Sowters, no. I have all that sort of thing done by the same specialist outfit that I use for my inductor designs. They're not that well known in audio circles and do a lot for operations like the aerospace industry. I won't be sharing their details if it's all the same as they do this work as a favour to me and don't wish to deal direct or in one off's for anyone but their commercial clients. I'm lucky enough to be included on their list in an arrangement with another company. Post edit: Case details below. It was from Douk Audio: www.ebay.co.uk/itm/Douk-Audio-Aluminum-Chassis-Case-for-Amplifier-DIY-Preamp-Enclosure-Cabinet-Box/261686263109?ssPageName=STRK%3AMEBIDX%3AIT&_trksid=p2057872.m2749.l2649Great news on the transformer delivery. I have a plan for it 😊 Fantastic case! I love it. Never popped up on my radar before. I have put it on my watched list. I'm more inclined to buy a Chinese case than a modushop one. I dont like the lack of support on the kids and bases from them, and every chinese one I have had has been fantastically well made. Looking forward to seeing how your build pans out. I think you're gonna enjoy it |

|

|

|

Post by electronumpty on Apr 27, 2020 19:25:53 GMT

A nice thick face plate on that case , looks the biz. I love the ideas of a space industry tx in there!

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Apr 27, 2020 20:05:44 GMT

Nice one thanks for the info and understand about the transformers.

It was Tiger Toroids I was thinking of so close with Norfolk lol......

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Apr 27, 2020 21:02:31 GMT

Nice, what case is that? oh and where are the transformers coming from, that place in Norfolk is it? I don't have the case details to hand but will dig them up as it might be useful for others. I think it was about £80 delivered which wasn't too bad. Usual Chinese fare but nicely made and very robust. Needs a fair few holes forming in the panels though! Transformers are not coming from Sowters, no. I have all that sort of thing done by the same specialist outfit that I use for my inductor designs. They're not that well known in audio circles and do a lot for operations like the aerospace industry. I won't be sharing their details if it's all the same as they do this work as a favour to me and don't wish to deal direct or in one off's for anyone but their commercial clients. I'm lucky enough to be included on their list in an arrangement with another company. Post edit: Case details below. It was from Douk Audio: www.ebay.co.uk/itm/Douk-Audio-Aluminum-Chassis-Case-for-Amplifier-DIY-Preamp-Enclosure-Cabinet-Box/261686263109?ssPageName=STRK%3AMEBIDX%3AIT&_trksid=p2057872.m2749.l2649I think that is the case that my Nuerochrome amps are built in. |

|

Bigman80

Grandmaster

The HiFi Bear/Audioaddicts/Bigbottle Owner

The HiFi Bear/Audioaddicts/Bigbottle Owner

Posts: 16,399

Member is Online

|

Post by Bigman80 on Apr 27, 2020 21:40:08 GMT

I don't have the case details to hand but will dig them up as it might be useful for others. I think it was about £80 delivered which wasn't too bad. Usual Chinese fare but nicely made and very robust. Needs a fair few holes forming in the panels though! Transformers are not coming from Sowters, no. I have all that sort of thing done by the same specialist outfit that I use for my inductor designs. They're not that well known in audio circles and do a lot for operations like the aerospace industry. I won't be sharing their details if it's all the same as they do this work as a favour to me and don't wish to deal direct or in one off's for anyone but their commercial clients. I'm lucky enough to be included on their list in an arrangement with another company. Post edit: Case details below. It was from Douk Audio: www.ebay.co.uk/itm/Douk-Audio-Aluminum-Chassis-Case-for-Amplifier-DIY-Preamp-Enclosure-Cabinet-Box/261686263109?ssPageName=STRK%3AMEBIDX%3AIT&_trksid=p2057872.m2749.l2649I think that is the case that my Nuerochrome amps are built in. It's a beauty. |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Apr 27, 2020 22:41:13 GMT

I thought the case wasn't bad value compared to some. Extruded case sides with the typical circular channelling which the machine screws thread the front and rear panels into. Front panel is 5mm thick and nicely finished. Anodising on all the black sections is flawless. Just got to make sure to use the star washers to bite through that when forming the chassis earth, or better still, grind a small section off first with the dremmel before fitting the star washer under the earthing eyelet.

Plenty of top ventilation for the valves as well as good clearance. Input IEC socket included. I may decide to change it for a larger fused one.

Just had to buy the mains latching switch, one of the few 240v led latching on/off switches I could find (most need an LV supply to the LED ring). If anyone else needs the part number I can provide that...it came from RS Components as did the lower rated switch for the MM/MC function.

Size of case is slightly more compact than full sized but not too tall. I'll be adding some graphics on the front with both Oli's Bigbottle Logo and the RFC logo....that design is still work in progress. It will be printed to water transfer acetate, applied and acrylic lacquered.

RCA sockets are robust and well made but inexpensive CMC ones and I've also bought a nickle plated earthing post which will also be grounded to the chassis in case any daisy-chain earthing is needed from the TT to the preamp or whatever. It may not be needed.

The case also comes with some nice rubber feet which are a decent size but I may use the soft rubber ones I use for my crossover boxes instead for better damping.

Internally I will be adding some damping to the base panel upon which the PCB/valves are mounted in the form of 2mm Silent Coat iso-elastomer.

Transformer will have a copper flux band added (I'll do yours for you Oli before I post it by wrapping in pure copper foil which I'll solder in place for you).

More as things progress but looking forward to some therapeutic DIY and next stage is to bring the stepped hole cutters into action!

|

|

Bigman80

Grandmaster

The HiFi Bear/Audioaddicts/Bigbottle Owner

The HiFi Bear/Audioaddicts/Bigbottle Owner

Posts: 16,399

Member is Online

|

Post by Bigman80 on Apr 27, 2020 23:10:05 GMT

I thought the case wasn't bad value compared to some. Extruded case sides with the typical circular channelling which the machine screws thread the front and rear panels into. Front panel is 5mm thick and nicely finished. Anodising on all the black sections is flawless. Just got to make sure to use the star washers to bite through that when forming the chassis earth, or better still, grind a small section off first with the dremmel before fitting the star washer under the earthing eyelet. Plenty of top ventilation for the valves as well as good clearance. Input IEC socket included. I may decide to change it for a larger fused one. Just had to buy the mains latching switch, one of the few 240v led latching on/off switches I could find (most need an LV supply to the LED ring). If anyone else needs the part number I can provide that...it came from RS Components as did the lower rated switch for the MM/MC function. Size of case is slightly more compact than full sized but not too tall. I'll be adding some graphics on the front with both Oli's Bigbottle Logo and the RFC logo....that design is still work in progress. It will be printed to water transfer acetate, applied and acrylic lacquered. RCA sockets are robust and well made but inexpensive CMC ones and I've also bought a nickle plated earthing post which will also be grounded to the chassis in case any daisy-chain earthing is needed from the TT to the preamp or whatever. It may not be needed. The case also comes with some nice rubber feet which are a decent size but I may use the soft rubber ones I use for my crossover boxes instead for better damping. Internally I will be adding some damping to the base panel upon which the PCB/valves are mounted in the form of 2mm Silent Coat iso-elastomer. Transformer will have a copper flux band added (I'll do yours for you Oli before I post it by wrapping in pure copper foil which I'll solder in place for you). More as things progress but looking forward to some therapeutic DIY and next stage is to bring the stepped hole cutters into action! Many thanks, Paul. Will you be adding any extra shielding around the traffo? I've not used one of these types before so i thought that was a pertinent question. Yes, soft feet are on the agenda for mine, as is a bit of vibration damping. The 2mm stuff looks ideal. Really looking forward to seeing the graphic. |

|

|

|

Post by jimbo on Apr 28, 2020 3:53:25 GMT

Almost all parts arrived now with transformer expected this week (you'll be pleased to hear yours is included Oli!). Work to start now on chassis which is surprisingly heavy and quite well made....dry-assembled with BBS pcb for scale in 2nd picture: Lots of work to do.... I wish I could be as neat working as you Paul.  Nice case BTW. |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Apr 28, 2020 7:20:34 GMT

Almost all parts arrived now with transformer expected this week (you'll be pleased to hear yours is included Oli!). Work to start now on chassis which is surprisingly heavy and quite well made....dry-assembled with BBS pcb for scale in 2nd picture: Lots of work to do.... I wish I could be as neat working as you Paul.  Nice case BTW. LoL...it doesn't stay that neat for long! I'm fast running out of storage drawers for components and almost 16ft of total wall length is taken up for small tools storage now. You have to be sort of neat when sharing a compact workshop with a medium (10" bladed) bench saw and router table plus dust extraction units and a couple of work benches.....more laid out like a kitchen with my swivel stool in the middle! @ Oli....you may not need to add any more shielding mate as it's not drawing much current so the emission field isn't that wide and I'll ensure that the whole core area is covered with the external flux band. If there is any residual hum (there shouldn't be) then a conductive (rather than Mu metal) shield in the form of an alloy or ferrous bracket bolted between the traffo and PCB is all that's needed. I would personally avoid mu metal as it can be a nightmare with some of the additional problems it can create if placed across a space like that. I know that Graham Tricker simply uses a copper plate neatly bent into an upright Z-section with the top leaf shielding over the top of the traffo and the vertical portion between the traffo and pcb and that works a treat. He does the same with his chokes and I think also uses flux bands. |

|

Bigman80

Grandmaster

The HiFi Bear/Audioaddicts/Bigbottle Owner

The HiFi Bear/Audioaddicts/Bigbottle Owner

Posts: 16,399

Member is Online

|

Post by Bigman80 on Apr 28, 2020 7:50:00 GMT

I wish I could be as neat working as you Paul.  Nice case BTW. LoL...it doesn't stay that neat for long! I'm fast running out of storage drawers for components and almost 16ft of total wall length is taken up for small tools storage now. You have to be sort of neat when sharing a compact workshop with a medium (10" bladed) bench saw and router table plus dust extraction units and a couple of work benches.....more laid out like a kitchen with my swivel stool in the middle! @ Oli....you may not need to add any more shielding mate as it's not drawing much current so the emission field isn't that wide and I'll ensure that the whole core area is covered with the external flux band. If there is any residual hum (there shouldn't be) then a conductive (rather than Mu metal) shield in the form of an alloy or ferrous bracket bolted between the traffo and PCB is all that's needed. I would personally avoid mu metal as it can be a nightmare with some of the additional problems it can create if placed across a space like that. I know that Graham Tricker simply uses a copper plate neatly bent into an upright Z-section with the top leaf shielding over the top of the traffo and the vertical portion between the traffo and pcb and that works a treat. He does the same with his chokes and I think also uses flux bands. Excellent, thanks Paul. I am looking forward to receiving it. |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Apr 28, 2020 10:01:23 GMT

I wish I could be as neat working as you Paul.  Nice case BTW. LoL...it doesn't stay that neat for long! I'm fast running out of storage drawers for components and almost 16ft of total wall length is taken up for small tools storage now. You have to be sort of neat when sharing a compact workshop with a medium (10" bladed) bench saw and router table plus dust extraction units and a couple of work benches.....more laid out like a kitchen with my swivel stool in the middle! @ Oli....you may not need to add any more shielding mate as it's not drawing much current so the emission field isn't that wide and I'll ensure that the whole core area is covered with the external flux band. If there is any residual hum (there shouldn't be) then a conductive (rather than Mu metal) shield in the form of an alloy or ferrous bracket bolted between the traffo and PCB is all that's needed. I would personally avoid mu metal as it can be a nightmare with some of the additional problems it can create if placed across a space like that. I know that Graham Tricker simply uses a copper plate neatly bent into an upright Z-section with the top leaf shielding over the top of the traffo and the vertical portion between the traffo and pcb and that works a treat. He does the same with his chokes and I think also uses flux bands. Flux bands!?! Need a pair of them for me diy Tardis; got the flux capacitors. And non of yer rubbish types either. And that'll have the time/interdimensional constant panel finished. It's all go here. |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Apr 28, 2020 11:06:05 GMT

Aye Jim, wee-out those flux bands she'll ne'er hold tigether! She'll break up Jim.....(followed by the "Clingon's on the starboard Bow, starboard bow, starboard bow" Chorus....)

|

|

|

|

Post by rexton on Apr 28, 2020 11:29:02 GMT

Aye Jim, wee-out those flux bands she'll ne'er hold tigether! She'll break up Jim.....(followed by the "Clingon's on the starboard Bow, starboard bow, starboard bow" Chorus....) Have you cracked open the whiskey already??  |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Apr 28, 2020 11:41:33 GMT

Not allowed sadly Andy. Have a blood disease which has damaged my liver and pancreas (not to mention giving me diabetes) so spirits are off menu for the foreseeable...What I wouldn't give for a glass of 15 yr old Lagaluvin!

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Apr 29, 2020 19:03:39 GMT

Ok...a bit more work on the BB3 build today. Courier arrived with my back order of inductors and the brand new BB3 transformers I had custom built, so I started by fitting the enclosure together to check that everything fitted together:  Next I set out the PCB and transformer on the base to check clearances and where the transformer would be best oriented. The sides and front were screwed back onto the base of the case and the transformer position optinised keeping it up towards the power input and rectifier stage of the PCB, as far from the delicate input signals as I could. I also remove the label from the traffo and wound several layers of copper flux banding to limite the radiating field. Finally, positions were all makred out and a vernier used on the reverse of the base to precisely measure and mark foir the holes to be drilled for the transformer and PCB mounting, and I then screwed them in to check fit. It's pretty hefty even at this stage thaks to a weighty case and an anchor of a transformer! This has been over-spec'd really and there's zero chance of this saturating or humming. I also fitted the IEC inlet and a temporary 1A fuse, later to be replaced with a more sensible 250mA fuse. So far, so good:

|

|

Bigman80

Grandmaster

The HiFi Bear/Audioaddicts/Bigbottle Owner

The HiFi Bear/Audioaddicts/Bigbottle Owner

Posts: 16,399

Member is Online

|

Post by Bigman80 on Apr 29, 2020 19:18:53 GMT

Ok...a bit more work on the BB3 build today. Courier arrived with my back order of inductors and the brand new BB3 transformers I had custom built, so I started by fitting the enclosure together to check that everything fitted together:  Next I set out the PCB and transformer on the base to check clearances and where the transformer would be best oriented. The sides and front were screwed back onto the base of the case and the transformer position optinised keeping it up towards the power input and rectifier stage of the PCB, as far from the delicate input signals as I could. I also remove the label from the traffo and wound several layers of copper flux banding to limite the radiating field. Finally, positions were all makred out and a vernier used on the reverse of the base to precisely measure and mark foir the holes to be drilled for the transformer and PCB mounting, and I then screwed them in to check fit. It's pretty hefty even at this stage thaks to a weighty case and an anchor of a transformer! This has been over-spec'd really and there's zero chance of this saturating or humming. I also fitted the IEC inlet and a temporary 1A fuse, later to be replaced with a more sensible 250mA fuse. So far, so good:

The traffo looks fine mate. Very tidy. |

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Apr 30, 2020 17:12:35 GMT

Some more progress today: Holes formed for switches, connections, PCB stand offs and transformer plus main chassis earth; Wiring routing sorted as best I could keeping signal well away from power; Transformer wired up; main on/off switch wired up and wiring ready for crimped connectors to be added for mains inlet. Just have some final wiring, signal sockets, MM/MC switch, input wiring, circuit testing and tidying up to finish.       |

|

|

|

Post by karma67 on Apr 30, 2020 17:16:32 GMT

nice work mate!

|

|

|

|

Post by jimbo on Apr 30, 2020 17:53:58 GMT

Looking good and traffo as far away as possible sulking in the corner!  |

|

Bigman80

Grandmaster

The HiFi Bear/Audioaddicts/Bigbottle Owner

The HiFi Bear/Audioaddicts/Bigbottle Owner

Posts: 16,399

Member is Online

|

Post by Bigman80 on Apr 30, 2020 18:10:50 GMT

Beautiful stuff.

Glad to see such a good level of build being put together.

For someone who said this would take an age, you have certainly flown through it lol

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on Apr 30, 2020 19:05:38 GMT

Thanks guys. I decided to play safe and put some metal bashing skills that I don't possess to work after cutting out some 1mm thick copper sheet. I've made a belt and braces traffo shield which via star washers under the case and into the copper shield earth it to chassis ground so hopeful the only humming that'll be going on will be me to the music!

|

|

|

|

Post by electronumpty on Apr 30, 2020 19:07:27 GMT

Loooking very tidy, have to say there was no issue with humming on mine but better safe than sorry if you can shield it.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on May 1, 2020 15:37:53 GMT

Completion day! Pictures pretty much document progress on order: -Rear panel connections fitted; -Internal wiring completed. Sensitive input signal is very low from my MC cart so I used a screened small diameter (Cardas Supreme) twin core overall screened cable with the screen connected at the input end then shunted to ground....belts and braces (again); -Switch for MM/MC added and wired in; -Earthing post added and set to a separate chassis earth from mains ground. I may at some point put a bridge rectifier and rfi cap plus small value resistor to this one if any earth loops appear and add a lift switch. - DIY bodgery for copper traffo screen added. I lacquered the copper in case of corrosion; - Valves added. Just got the crimp connectors to do for the mains (left until last to prevent silly accidents) and we're away!        |

|

Bigman80

Grandmaster

The HiFi Bear/Audioaddicts/Bigbottle Owner

The HiFi Bear/Audioaddicts/Bigbottle Owner

Posts: 16,399

Member is Online

|

Post by Bigman80 on May 1, 2020 15:55:45 GMT

Bang Tidy, Paul

Fantastic job.

How did you bend the Copper plate? Presuming a big vice maybe.

|

|

Deleted

Deleted Member

Posts: 0

|

Post by Deleted on May 1, 2020 16:06:30 GMT

Thanks Oli and thank you for all your responses to queries on some of the techy bits. Bending the copper plate: A big vice and nylon fronted hammer with a block of scrap plywood between it and the copper. We have power and everything lights up....a big bonus is that I didn't turn to a toasty crisp when I switched it on! Earth continuity between panels testes and within 0.1 Ohms all round. Close up, and I mean with my ear a few inches from the case I can hear a slight hum of the transformer but you wouldn't be able to hear this from a metre or two away.

I assume that the red LEDs are lit in "MC" mode? They go off if I throw the switch anyway. I just have the front panel decals and some lettering for the rear of the casework to finish all off to do now. |

|

|

|

Post by firebottle on May 1, 2020 16:23:54 GMT

LED's are lit in MM mode, that is with the relays energised.

The design has the relays unpowered in MC mode so there is no possibility of any ripple on the relay supply from coupling into the sensitive MC input. The MC input isn't switched btw.

Don't throw the switch unless the volume is at minimum, there is a large perturbation in output when switching.

|

|